Precision Extruded Rubber Solutions

for Automotive Excellence

PRODUCT CATEGORY

Fuqiang delivers precision-engineered custom rubber extrusions, ensuring superior sealing, durability, and OEM compatibility.

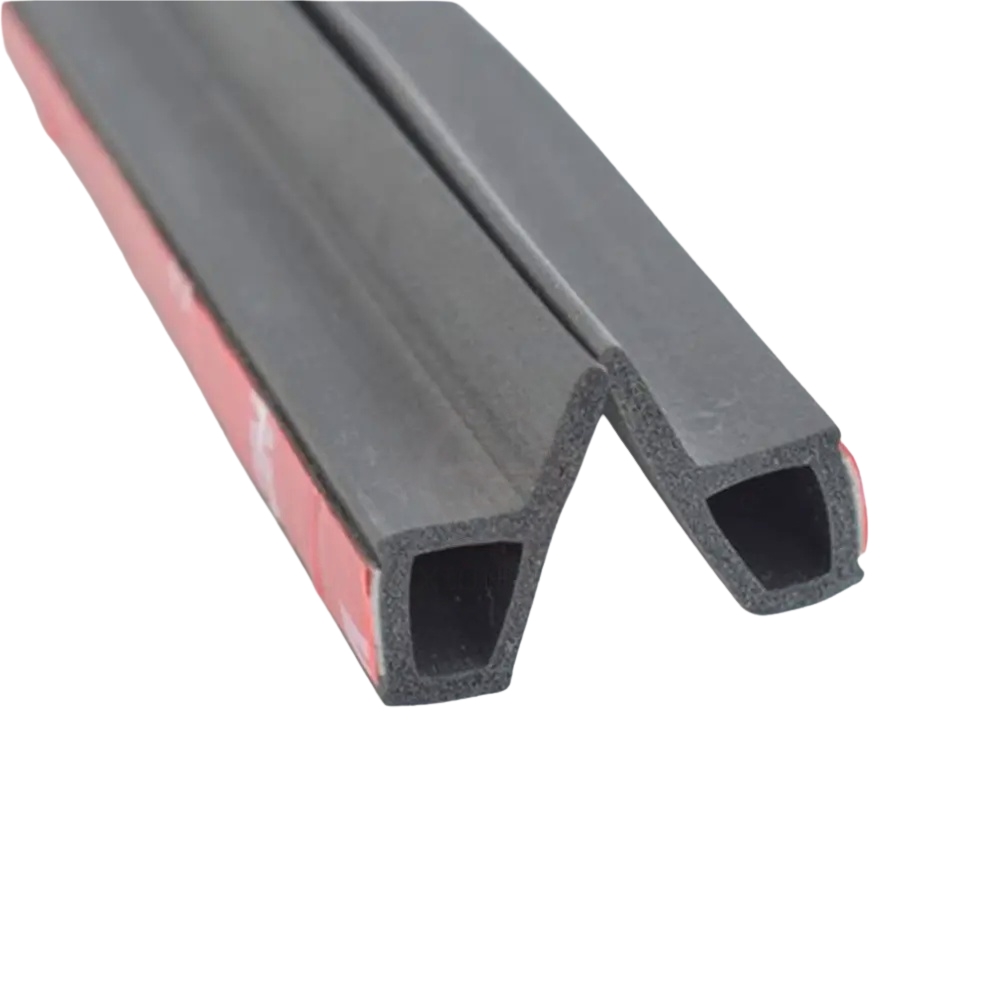

Dense rubber extrusion

Material: TPE+copper wire+tape

Process: TPE extrusion - adhesive backing - cutting - TPE bonding - trimming / back bending corner tape - packaging

Dense rubber extrusion

Material: TPE+copper wire+tape

Process: TPE extrusion-adhesive backing-cutting-TPE bonding-trimming/back bending tape-thermal welding-trimming-packaging

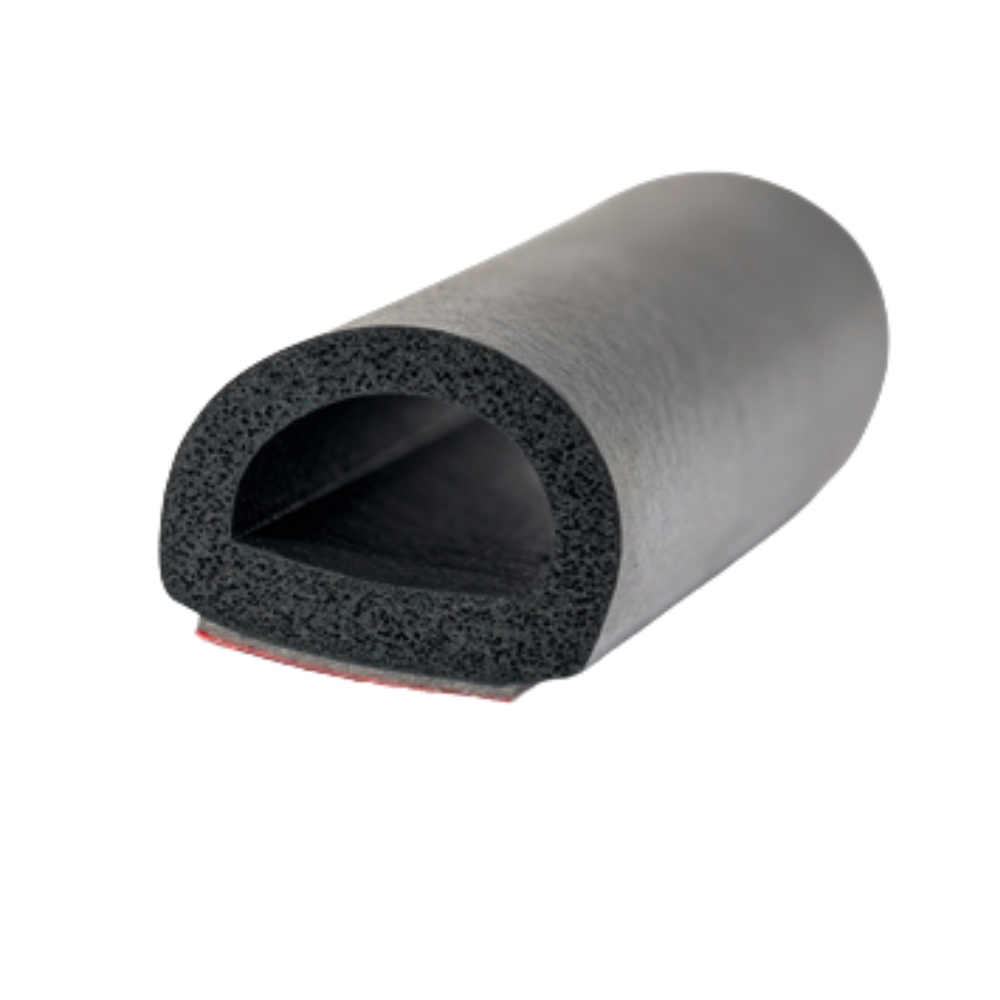

Foam Rubber Extrusion

Material: EPDM Sponge + 3M/Soken Tape

Process: EPDM extrusion - adhesive backing - cutting - packaging

Foam Rubber Extrusion

Material: EPDM Sponge + 3M/Soken Tape

Process: EPDM extrusion - adhesive backing - cutting - packaging

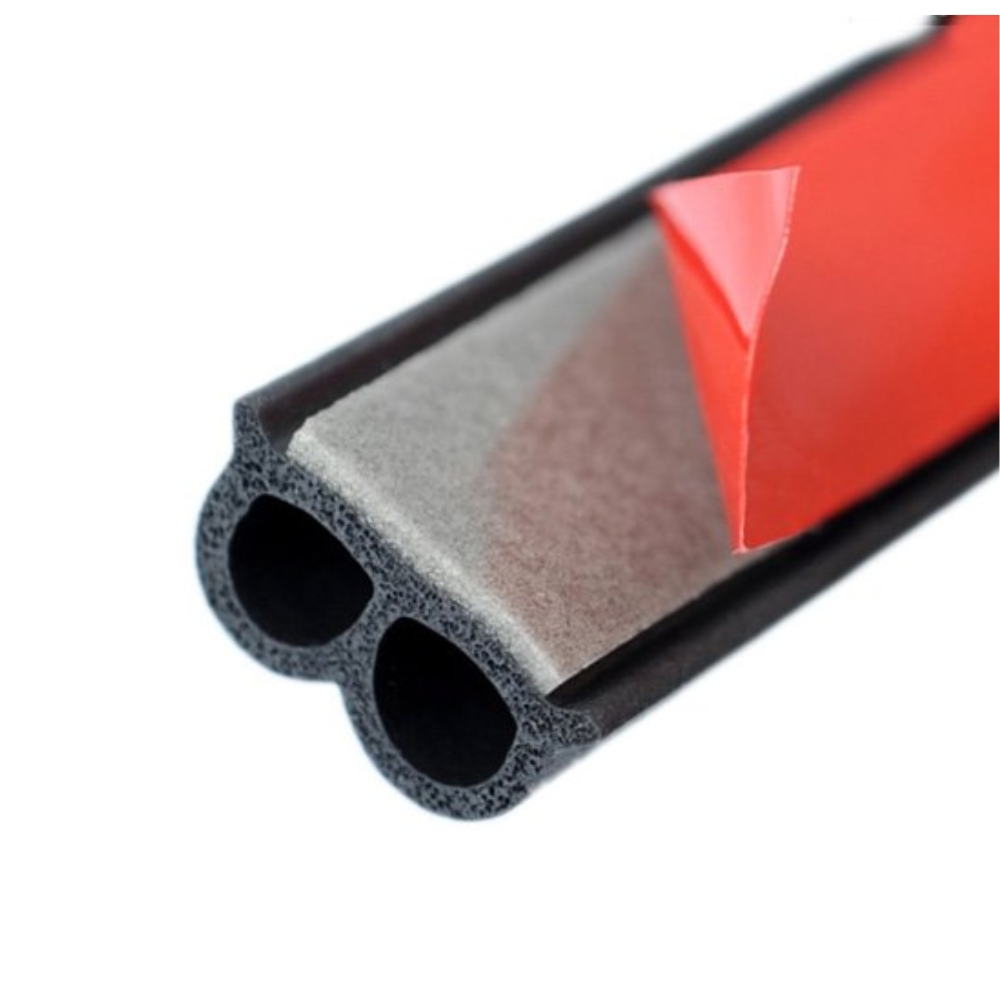

Compound rubber extrusion

Material: EPDM Dense + EPDM Sponge + Steel Carrier

Process: EPDM Extrusion - Cutting - Joining - Trimming - Inspection - Packaging

Compound rubber extrusion

Material: EPDM Dense + EPDM Sponge

Process: EPDM Extrusion - Cutting - Joining - Trimming - Inspection - Packaging

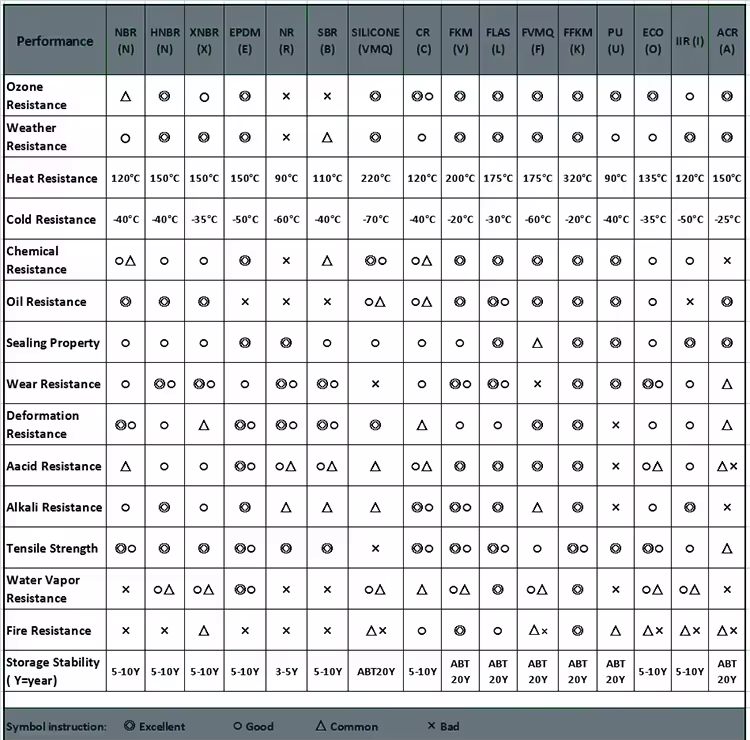

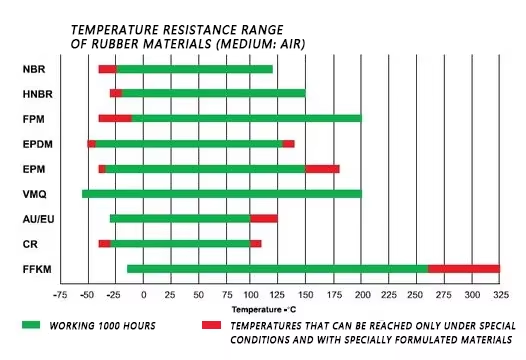

Material Introduction

Customized Rubber Seal

Automotive Applications

Our precision extruded rubber solutions protect and enhance vehicle systems across entire platforms,from conventional powertrains to next-generation electric vehicles.

Door Seal Systems

Automotive door weatherstrips are mounted to the door panel using adhesive backing or plastic fasteners (retaining clips), forming the primary seal between the door and vehicle body to effectively block ingress of external contaminants including water, dust, wind noise and airborne particles.

Luggage Weatherstrips

Tailgate weather seals install along body panel edges to form a secure barrier against moisture, air and contaminants entering the cargo area. Our proprietary EPDM formulations deliver superior permanent set resistance, mechanical strength, and outstanding resistance to weathering, UV, chemicals and extreme temperatures.

Sunroof sealing strip

Sunroof seals strips are installed along sunroof openings to prevent water, noise and air leakage, our EPDM rubber compounds offer excellent UV resistance, compression set properties, water resistance and temperature stability from -40°C to 120°C.

Door Glass Runs

Door Glass Runs can be extruded in different geometries and sizes to meet automotive sealing needs. The main material choice is EPDM compounds, and the products include: Door Glass Runs (flocking lined or surface coated models), Fiber Impregnated Rubber Runs, Flocked Integrated Glass Runs and other non-reinforced all-rubber runs with optional flocked/coated inner surfaces.

Material Excellence

Engineered automotive sealing solutions using advanced materials for unmatched durability and performance

EPDM Extrusions for Automotive Sealing

Application: Door seals, window seals (primary and secondary), trunk seals, hood seals, sunroof seals, edge trims.

Material_Choice: EPDM (Ethylene Propylene Diene Monomer) Rubber

Hardness:40-90 Shore A, Temp Range: -50°C to 150°C, Weathering:15+ year life

Material_Advantages: Excellent weather, ozone, UV, and aging resistance. Wide temperature range (-50°C to 150°C). Good compression set. Ideal for dynamic and static automotive sealing applications, ensuring long-term durability and protection against elements.

TPV/TPE Profiles for Interior & Exterior Trim

Application: Window encapsulations, beltline seals, cowl screen seals, interior decorative trims, soft-touch components.

Material_Choice: TPV (Thermoplastic Vulcanizate) / TPE (Thermoplastic Elastomer)

Hardness:50-95 Shore A, Temp Range:-40°C to 135°C, Compression Set:<10% after 22h

Material_Advantages: Good flexibility, colorability, recyclability, and chemical resistance. Offers design freedom and can be co-extruded with rigid plastics. Provides a balance of rubber-like properties and thermoplastic processability for cost-effective solutions.

Specialized Materials for NEV Battery Safety

Application: Battery pack perimeter seals, module-to-module seals, thermal runaway protection, fireproof insulation barriers, compression pads.

Material_Choice: Silicone Foam, Mica Sheets, Aerogel, MPP (Modified Polyphenylene)

Material_Advantages: Exceptional flame retardancy (UL94 V-0), high-temperature resistance, low thermal conductivity, excellent electrical insulation, and long-term sealing performance. Critical for enhancing safety and longevity of NEV battery systems.

Our Services

Custom Profile Extrusion

Tailored EPDM, TPV, TPE profiles designed to your exact specifications for optimal fit and performance.

Automotive Sealing Solutions

Specialized in car door, window, edge trim, and self-sealing window channels for superior protection.

Co-Extrusion Expertise

Dual durometer profiles with metal or wire carriers, offering enhanced durability and functionality.

OEM/ODM Manufacturing

Full-service OEM/ODM for custom automotive components, from design to mass production globally.

Material Development & Innovation

Leveraging 134 patents to develop and apply advanced materials for your unique applications.

Save Cost

1. Due to our huge production capacity, we have an advantage in raw material procurement costs.

2. We have factories abroad, saving you shipping and time costs

Our Clients

Li Wei

"We've partnered with Fuqiang for several years on various TPE profiles. Their consistent quality, on-time delivery, and competitive pricing have made them a reliable and strategic supplier. Their global footprint aligns perfectly with our production needs."

Sarah Chen

"The low PPM defect rate from Fuqiang's co-extruded sealing strips is impressive. Their adherence to IATF 16949 standards and transparent quality control processes give us immense confidence in their products. They are a key partner in maintaining our vehicle quality."

David Miller

Our Services

Full-service from design to delivery including material selection, DFM analysis, tooling fabrication, and logistics support for JIT programs. Our engineering team works closely with clients from concept to production, ensuring seamless integration of our extruded components into your assemblies.

1.Material Selection

Expert guidance on optimal rubber compounds for your application requirements

2.Design Optimization

CAD/CAE simulation to validate performance before tooling

3.Production Planning

Capacity allocation and quality planning for smooth ramp-up

Development Process

Proven development methodology,our structured development process reduces time-to-market while ensuring all technical and quality requirements are met:

1.Requirements Analysis

Detailed application review with CAD/CAE simulation to validate design.

2.Material Validation

Compound formulation & process validation for optimal performance.

3.Prototyping

Fast-turn samples with 3D printed/CNC tooling for functional testing.

3.Production Approval

Full production tooling & PPAP documentation package.

Customization Process

Our systematic approach to custom rubber extrusion projects ensures technical and commercial success at every stage:

1.Application Review

Detailed requirements gathering including environment, loads, and interfaces.

2.CAD Modeling

3D design with DFM analysis for manufacturability and cost optimization.

3.Material Selection

Compound recommendation based on performance and cost targets.

4.Prototyping

Functional samples for validation testing within 1-2 weeks.

5.Testing Validation

Complete physical and environmental testing to verify performance.

6.Mass Production

Seamless transition to volume manufacturing with quality controls.

Process Capability

Our manufacturing systems combine precision engineering with process innovation to deliver exceptional rubber components:

1.Continuous Vulcanization

High-speed extrusion up to 25m/min with precise temperature control (±1°C) for consistent cross-linking.

2.Co-extrusion

Dual-durometer profiles with ±0.05mm tolerance for complex sealing applications.

3.Metal Insertion

Precision placement of steel carriers and wire reinforcements for structural applications.

4.Post-processing

CNC cutting (±0.1mm), punching, notching, and assembly operations for finished components.

5.Surface Treatments

Plasma activation, laser etching, flocking, and specialty coatings to enhance performance.

Technical Capability

Through sustained R&D investment, we've developed specialized competencies that address the most demanding automotive applications:

1.Temperature Performance

Advanced EPDM formulations operational from -50°C to 150°C ambient, with 200°C short-term capability.

2.Elastomer Engineering

TPE/TPV profiles with 300%+ elongation and <10% compression set for long service life.

3.Flame Resistance

UL94 V-0 rated compounds for EV battery and high-voltage applications.

4.EMI Shielding

Conductive formulations <5 ohm/cm for faraday cage and grounding applications.

5.NVH Solutions

Acoustic dampening profiles achieving 30dB+ noise reduction in cabin applications.

Quality Control Process

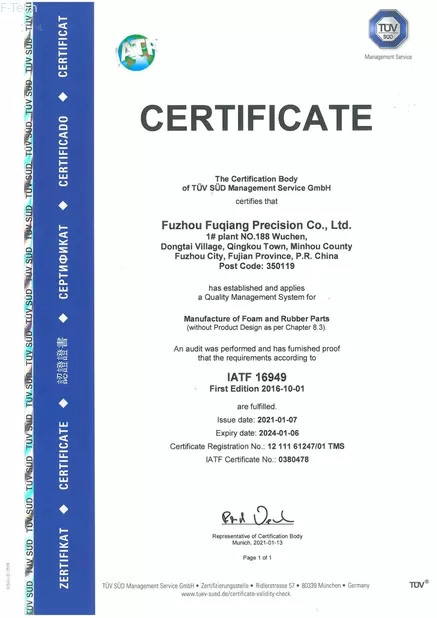

IATF 16949 certified, our QC involves raw material inspection, in-process checks, dimensional verification, performance testing (e.g., compression set, tensile strength), and final outgoing inspection.

Secondary Processing Capability

We offer value-added secondary processes including precision cutting to length, drilling, notching, adhesive application, flocking, PU coating, and assembly of components to streamline your supply chain.

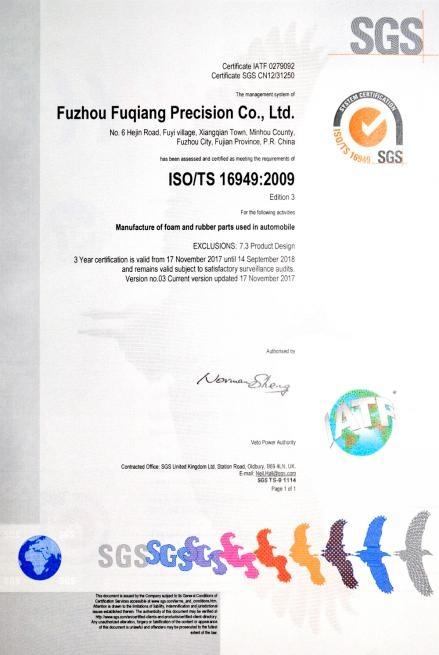

Certificates

Our quality management systems meet the highest international standards, with full compliance to automotive-specific requirements including IMDS reporting,

PPAP documentation, and production part approval processes.

ISO 45001

ISO4001

IATF 16949

ISO/TS 16949

OHSA18001

Expanding Our Expertise to Other Industries

While automotive is our core, Fuqiang's precision extrusion and sealing technology is adaptable. We are exploring applications in Engineering Machinery (excavators, cranes, bulldozers, road pavers) and Agricultural Machinery (harvesters, tractors, mowers, balers). If you require high-quality, durable sealing solutions for heavy-duty equipment, we welcome your inquiries to discuss how our capabilities can meet your specific needs.

Bus And Coach

Machinery Industry

Heavy Truck

FAQ

What types of rubber materials do you specialize in for automotive extrusions?

We primarily specialize in EPDM, TPV, TPE, and Silicone (especially for foam and EV applications). We can also work with other materials based on specific project requirements.

Can you manufacture custom rubber extrusion profiles based on our design?

What is your typical lead time for new tooling and first article samples?

Which quality certifications do you hold for the automotive industry?

How do you ensure consistent quality in high-volume production runs?

What are your capabilities for co-extruded seals (e.g., with metal carriers)?

We have advanced co-extrusion lines for dual durometer profiles, incorporating metal cores (solid or segmented steel, wire) and different materials for optimal performance.

Do you offer solutions for New Energy Vehicle (NEV) battery pack sealing and insulation?

How do you support clients with material selection for their applications?

Can you provide material data sheets and compliance documentation (e.g., IMDS, RoHS)?

What secondary operations or finishing services do you offer for extruded parts?

Start Your Custom Extruded Rubber Project Today

Our engineers are ready to assist.

MORE ABOUT FQ

CONTACT US

Wuchen 188, Dongtai Industrial Zone

Qingkou Town, Minhou County

Fuzhou, Fujian 350119 China

+86 15980202009 (WhatsApp)

+86 15980202009

fq10@fzfuqiang.cn

Copyright © 2024 EM-INDUSTRY. All Rights Reserved. Sitemap. Privacy Policy.