2026-02-18 Optimize Thermal Management with EPDM Cooling Hoses & ConnectorsIntroductionIn a modern electric vehicle, the Thermal Management System (TMS) is the heart of efficiency. It actively cools the battery during charging, warms it in winter, and cools the e-motor. This complex network of "plumbing" requi

Read More

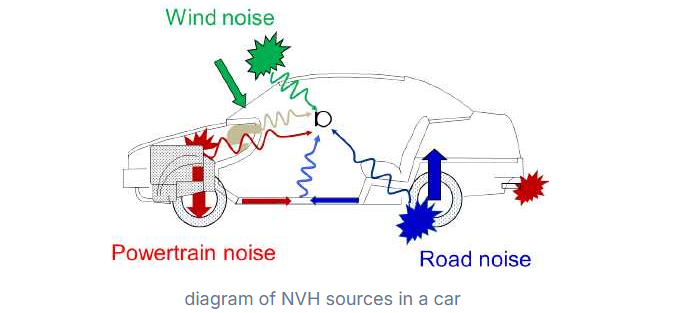

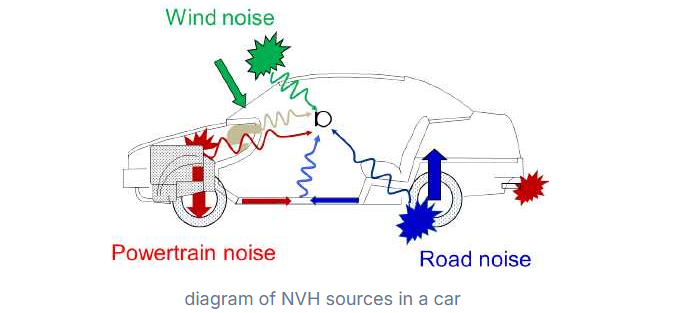

2026-02-13 Silence the Ride: Advanced NVH Rubber Solutions for Electric VehiclesIntroductionElectric Vehicles are quiet—too quiet. Without the masking noise of an internal combustion engine, every squeak, rattle, and road vibration becomes amplified. This has elevated NVH (Noise, Vibration, and Harshness) engi

Read More

2026-02-12 Protect EV Batteries: The Critical Role of Silicone Foam & EPDM SealsIntroductionIn the world of New Energy Vehicles (NEVs), the battery pack is the most expensive and critical component. A single drop of water ingress can lead to a catastrophic short circuit or thermal runaway.While much attention

Read More

2026-02-12 Increase Seal Integrity with Custom Rubber O-RingsTitle: Prevent Fluid Leaks with High-Precision Rubber O-RingsIntroduction:A single failing rubber O-ring can shut down an entire production line. These tiny circular seals are critical for hydraulic and pneumatic systems. When you buy rubber O-rings

Read More

2026-02-11 Soundproof Your Cabin with Rubber Damping SheetsTitle: Achieve Luxury Silence using Rubber Damping SheetsIntroduction:Road noise is the enemy of a premium driving experience. Rubber damping sheets (or deadening mats) are the industry standard for acoustic control. By applying rubber damping sheets,

Read More

2026-02-10 Enhance Fluid Transfer with Reinforced Rubber HosesTitle: Ensure Leak-Free Performance with Automotive Rubber HosesIntroduction:Modern engines operate under extreme pressure. Reliable rubber hoses are essential for coolant and fuel delivery. Without high-grade rubber hoses, engine overheating is in

Read More

2026-02-09 Protect Engine Components with Custom Rubber GrommetsTitle: Secure Wire Routing with Industrial Rubber GrommetsIntroduction:In the world of automotive wiring, protection is everything. Rubber grommets prevent sharp metal edges from cutting through electrical insulation. By installing rubber grommets

Read More

2026-02-07 Reduce Vibration Using Automotive Rubber BushingsTitle: Optimize Suspension Stability with Heavy-Duty Rubber BushingsIntroduction:Driving comfort depends entirely on how well your vehicle handles road energy. Rubber bushings act as the joints of your suspension system. High-performance rubber bushi

Read More

2026-02-06 Maximize Vehicle Longevity with Precision Rubber WeatherstripsTitle: Upgrade Vehicle Sealing Performance with High-Density Rubber WeatherstripsIntroduction:Are you struggling with cabin noise or water leaks in your automotive designs? Rubber weatherstrips are the silent heroes of vehicle longevity.

Read More

2026-01-29 Don't let your IP68 product fail due to rubber "fatigue." This guide explains why Compression Set is more critical than tensile strength for waterproof wire harnesses and how Fuqiang's peroxide-cured materials ensure long-term sealing memory.

Read More