Rubber Molded Shock Absorber Components for Enhanced Vibration Control and Durability

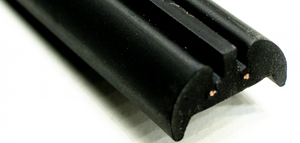

Shock absorber components play a critical role in the smooth and safe operation of vehicles, and our Rubber Molded Shock Absorber Components are engineered to deliver superior vibration dampening and impact resistance. These rubber parts are created using advanced injection molding technology, ensuring they meet the stringent requirements of modern automotive applications. Our components are ideal for use in various vehicle systems, providing consistent performance in challenging environments.

Key Features and Benefits:

Precision Rubber Injection Molding:Our shock absorber components are crafted using high-precision rubber injection molding techniques. This ensures that each part is manufactured with the utmost accuracy, providing a perfect fit and enhancing the overall performance of vehicle suspension systems.

Durable and Long-Lasting:These components are engineered to withstand extreme conditions, from temperature fluctuations to mechanical stress. Our molded rubber parts provide long-lasting durability, ensuring reliable performance even under harsh driving conditions.

Temperature Resistance: Capable of withstanding both high and low temperatures, ensuring consistent performance across various climates.

Impact Resistance: Absorbs shocks and vibrations effectively, reducing wear on other vehicle parts.

![52]()

Vibration and Noise Dampening:Our rubber molded shock absorber components are designed to minimize road vibrations and reduce noise levels within the vehicle cabin. This improves ride comfort and vehicle stability.

Vibration Control: Effectively dampens road shocks, providing a smoother ride.

Noise Reduction: Reduces noise transmission from the road, improving overall cabin comfort.

Custom Rubber Formulations:We offer a wide range of rubber formulations, including EPDM, NBR, and silicone, ensuring that the components are tailored to meet specific performance requirements. Our custom rubber solutions guarantee high resistance to oils, fuels, and environmental factors.

EPDM: Known for its excellent weather, ozone, and UV resistance, making it ideal for outdoor automotive applications.

NBR: Provides outstanding oil and fuel resistance, ensuring reliable performance in engine and transmission systems.

Wide Range of Automotive Applications:Our rubber molded shock absorber components are suitable for a variety of automotive systems, including suspension, chassis, and other vehicle components that require effective shock absorption and noise dampening.

Shock Absorber Systems: Custom rubber components designed to improve the performance and longevity of automotive shock absorbers.

Automotive Seals and Gaskets: Provides excellent sealing and protection in engine, transmission, and other critical vehicle systems.

Technical Specifications:

| No. | Property | Unit | Test Standard | Value |

| 1 | Tensile Strength | MPa | ASTM D412 | ≥12 |

| 2 | Elongation at Break | % | ASTM D412 | ≥300 |

| 3 | Hardness (Shore A) | Shore A | ASTM D2240 | 50-80 |

| 4 | Compression Set | % | ASTM D395 | ≤20 |

| 5 | Operating Temperature Range | °C | - | -40°C to 150°C |

| 6 | Ozone Resistance | / | ASTM D1149 | Pass |

| 7 | Oil and Fuel Resistance | / | ASTM D471 | Excellent |

Applications of Rubber Molded Shock Absorber Components:

Suspension Systems:Our rubber components are ideal for use in automotive suspension systems, where vibration dampening is essential for ensuring smooth vehicle operation. These parts are designed to absorb road impacts and reduce wear on critical suspension components.

Chassis and Body Mounts:These molded rubber parts are also used in vehicle chassis and body mounts, helping to reduce vibration transmission from the road and enhancing vehicle stability.

Engine and Transmission Systems:Our rubber molded components are widely used in engine and transmission systems, where they provide sealing, vibration control, and noise reduction, ensuring optimal engine performance.

Custom Automotive Applications:Whether for gaskets, seals, or specialized components, our custom rubber molded parts can be tailored to meet specific requirements for any automotive application.

Why Choose Our Rubber Molded Shock Absorber Components?

Advanced Injection Molding Expertise:We bring years of experience in rubber injection molding, providing precision-engineered components that meet the exacting standards of the automotive industry. Our expertise ensures that each part is crafted with precision, offering long-term durability and performance.

Comprehensive Material Selection:We offer a wide variety of rubber materials, including EPDM, NBR, and silicone, to suit different applications and environments. Each material is selected based on its ability to provide optimal performance in specific automotive systems.

Fast Production and Competitive Pricing:We understand the importance of meeting deadlines and offer quick production times to ensure your project stays on track. Our efficient processes also allow us to provide competitive pricing without compromising on quality.

Custom Solutions for Every Application:Our rubber molded shock absorber components can be customized to meet the unique requirements of your automotive system. Whether you need specific sizes, materials, or performance characteristics, we provide the perfect solution for your project.

Contact Us for Custom Rubber Molded Shock Absorber Components:

Looking for high-quality rubber molded shock absorber components for your vehicles? Contact us today to learn more about our custom solutions for automotive applications. Our team of experts is ready to help you find the perfect components for your vehicle's suspension, chassis, and other critical systems.