We are provider of automotive sealing solutions.Our extruded EPDM,TPE,TPV, molded rubber and foam die cut components are mainly applied in automotive industry.We are trusted by Tier 1 like Magna,Inalfa,Hutchinson,WKW,Fuyao,Minth and so on.

Welcome to contact us for more details

Kiss-Cut Foam Die Cut: Precision and Versatility for Your Foam Needs

Introduction

Our Kiss-Cut Foam Die Cut solutions offer exceptional precision and versatility for various applications. Perfect for creating custom foam components, these die-cut parts are ideal for a wide range of industries, including automotive, electronics, and packaging. With our high-quality foam die cut capabilities, you can achieve the exact specifications and performance requirements you need.

Product Features

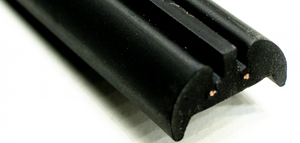

Versatile Foam Types: We provide die-cut solutions for a broad array of foam materials, including PU foam, EPE, EPDM, EVA, and more. Whether you need kiss-cut foam gaskets or other specialized foam die cut parts, we have the material to meet your needs.

Precision Kiss-Cutting: Our kiss cut foam process ensures clean, accurate cuts while leaving the backing intact. This method is ideal for producing foam die cut gaskets and other custom shapes, making handling and application straightforward and efficient.

High Performance and Reliability: Our foam exhibits a range of desirable characteristics:

Excellent Shielding: Provides a shielding effectiveness of more than 90dB at low pressure.

Elastic and Lightweight: Ensures easy handling and application.

Anti-Corrosion Coating: Nickel coating prevents electrochemical corrosion.

Low Surface Contact Resistance: Promotes effective electrical performance.

Fast Pressure-Sensitive Fixing: Allows for quick and reliable application.

Customizable Options: We offer the ability to specify lengths and select from a variety of cross-sections. Our foams are UL grade fireproof and can be customized to meet specific requirements, including hardness and texture based on foam density and bubble size.

Applications: Ideal for use in various settings, from automotive to electronics. Kiss-cut foam can be used for creating gaskets and protective components, providing both functional and aesthetic benefits.

Why Choose Us?

Expertise in Foam Die Cutting: Our advanced techniques ensure precision and consistency in every cut.

Diverse Foam Options: We handle a wide range of foam types and specifications to meet diverse needs.

Custom Solutions: Tailor-made solutions to fit your exact requirements.

Conclusion

For high-quality kiss-cut foam die cut solutions that deliver precision, durability, and versatility, choose our services. Whether you need foam die cut parts for automotive applications or other industries, our expertise ensures that you receive the best products tailored to your needs. Contact us today to learn more about how our foam die-cutting capabilities can benefit your projects.