Precision Rubber Injection Molding for Automotive Rubber Components High-Performance Custom Molding Solutions

Introduction:

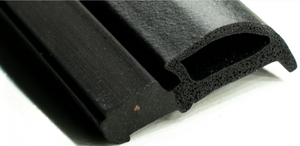

At Fuqiang, we specialize in Precision Rubber Injection Molding to produce premium rubber components for the automotive industry. Our injection molding process ensures that each rubber part meets tight tolerances, offering exceptional sealing, insulation, and vibration control for optimal vehicle performance and longevity. These custom-molded rubber parts are essential for engine systems, door seals, gaskets, and more.

Key Features:

1. High Precision Injection Molding

Our injection molding process ensures that each rubber component for automotive applications is manufactured to exacting standards, offering tight tolerances and precise fitments. This guarantees reliability and long-term performance even in harsh environments.

2. Custom Rubber Components for Automotive Use

We offer customized molding solutions for a wide range of automotive rubber parts, including seals, gaskets, boots, bumpers, and insulation components. Each product is tailored to meet specific design and functional requirements.

3. High-Performance Materials

Our rubber components are made from durable, high-performance materials such as EPDM, NBR, SBR, and silicone. These materials offer excellent resistance to heat, chemicals, oil, and weathering, making them ideal for long-term use in automotive environments.

4. Vibration Dampening and Noise Reduction

Our injection-molded rubber parts provide effective vibration dampening and noise reduction, improving vehicle comfort while reducing wear on components such as engine mounts, bushings, and door seals.

Applications:

1. Automotive Seals and Gaskets

Our precision injection-molded rubber seals and gaskets offer reliable sealing for automotive engines, doors, and windows, protecting against moisture, dust, and air leakage.

2. Rubber Components for Engine Systems

Injection-molded rubber parts play a critical role in engine systems, providing insulation, sealing, and vibration control, improving performance and reducing wear on mechanical components.

3. Vibration-Dampening Rubber Parts

Our custom-molded rubber components are engineered to absorb vibrations and minimize noise, improving ride comfort and extending the lifespan of automotive systems.

4. Automotive Rubber Boots, Bumpers, and Insulation Parts

We provide custom rubber boots, bumpers, and insulation parts for automotive use, offering flexibility, durability, and impact protection in critical areas of the vehicle.

Why Choose Our Precision Rubber Injection Molding Services?

Our Precision Rubber Injection Molding services are focused on creating high-performance, custom rubber components for automotive applications. From seals and gaskets to vibration-dampening parts and more, our advanced injection molding process ensures tight tolerances, high precision, and consistent quality. We are a trusted source for automotive manufacturers and OEM suppliers alike.

Customization Options:

Our injection-molded rubber components offer numerous customization options, including:

Custom sizes, shapes, and thicknesses

Selection of rubber materials tailored to specific performance needs, including EPDM, NBR, and silicone

Custom color matching for vehicle components

Material properties tailored for heat resistance, chemical resistance, and vibration control

Industries Served:

Automotive Manufacturing

Heavy Machinery

Aerospace

Industrial Equipment

Consumer Electronics

Conclusion:

Our Precision Rubber Injection Molding solutions deliver exceptional performance, durability, and precision for automotive rubber components. By offering superior material properties, custom design capabilities, and precise manufacturing processes, we provide injection-molded rubber parts that meet the exact needs of your vehicle, ensuring lasting reliability and optimal performance even in the most demanding automotive applications.