We are provider of automotive sealing solutions.Our extruded EPDM,TPE,TPV, molded rubber and foam die cut components are mainly applied in automotive industry.We are trusted by Tier 1 like Magna,Inalfa,Hutchinson,WKW,Fuyao,Minth and so on.

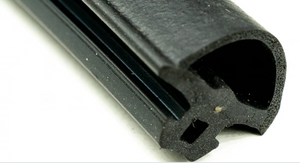

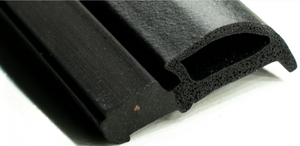

Our Molded Rubber EPDM Sealing Strip is crafted from high-quality ethylene propylene diene monomer (EPDM), a synthetic elastomer renowned for its exceptional durability and resistance to harsh environmental conditions. This versatile material is widely used across various industries, including automotive, construction, HVAC, and water management.

Properties of Molded Rubber EPDM:

Weather Resistance: Our molded EPDM rubber withstands extreme temperatures, UV radiation, and ozone exposure without deteriorating, ensuring long-lasting performance in challenging environments.

Chemical Resistance: EPDM rubber offers excellent resistance to alcohols, greases, detergents, ketones, silicone oils, and mild acids, making it suitable for a wide range of applications.

Cost-Effective: Compared to silicone, EPDM rubber is more economical while providing similar benefits to neoprene, making it a cost-effective solution for many sealing needs.

Electrical Insulating Properties: With outstanding electrical insulating characteristics, molded EPDM rubber is ideal for applications requiring electrical safety and insulation.

Limitations: While EPDM molding provides many advantages, it is not suitable for applications involving petroleum derivatives, as mineral oils and solvents can cause adverse reactions.

Storage Recommendations: To maintain the integrity of molded EPDM rubber, store it in a cool, dry place with temperatures below 75°F. Avoid exposure to direct heat, open flames, and sunlight to ensure long-term durability.

Our EPDM injection molding process ensures precision and consistency in every strip, providing reliable performance and durability for your sealing needs. Choose our molded EPDM sealing strips for a high-quality, cost-effective solution that meets the demands of your industry.