Custom Bespoke Molded Rubber Solutions for Auto Parts And Industrial Applications

Key Features and Benefits

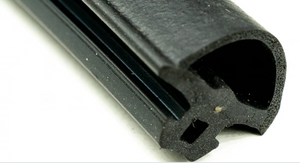

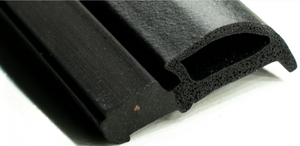

Tailored Rubber Moulding

We specialize in engineering custom rubber parts precisely tailored to your application's unique requirements. Our advanced molding processes guarantee high-precision manufacturing, ensuring optimal performance and consistency in every component we deliver.

Custom Fit: Custom-tailored rubber parts designed to precisely meet the specifications of your automotive or industrial systems, ensuring seamless integration.

Precision Moulding: Utilizing advanced techniques, we specialize in producing rubber parts with intricate designs and tight tolerances.

Durability and Longevity

Our durable molded rubber parts are engineered for long-term performance in harsh environments, such as extreme temperatures, chemical exposure, and mechanical stress. They are built to provide consistent performance over the course of their lifespan.

Temperature Resistance: Capable of performing in both high and low-temperature environments.

Chemical Resistance: Engineered to resist damage from oils, fuels, and various industrial chemicals.

Wide Range of Applications

At our factory in Indiana, we produce rubber components that exceed the highest standards for quality and reliability to meet diverse industrial needs.

Automotive Parts: Custom-fit seals, gaskets, and vibration dampeners designed for vehicles.

Industrial Equipment: Rubber parts designed specifically for use in heavy machinery and equipment to provide protection and improve performance.

Flexible Material Options

Our inventory of rubber compounds includes EPDM, NBR, silicone, and neoprene to meet every project need with maximum performance and longevity in mind. We ensure the appropriate material selection for every task to guarantee optimal performance and durability.

EPDM: Ideal for outdoor applications due to its excellent resistance against weather, UV radiation, and ozone damage.

NBR: Renowned for its oil and fuel resistance properties, making it perfect for automotive or industrial fluid handling systems.

Affordable Solutions

Our custom moulding processes are designed to minimize waste and maximize production efficiency, allowing us to provide high-quality custom rubber parts at competitive prices. Whether you need a small or large production volume, we offer cost-effective solutions tailored to your needs.

Technical Specifications

| No. | Property | Unit | Test Standard | Value |

| 1 | Tensile Strength | MPa | ASTM D412 | ≥12 |

| 2 | Elongation at Break | % | ASTM D412 | ≥350 |

| 3 | Hardness (Shore A) | - | ASTM D2240 | 40-90 |

| 4 | Compression Set | % | ASTM D395 | ≤25 |

| 5 | Operating Temperature Range | °C | - | -40 to 120 |

Applications

Automotive Seals and Gaskets

Our custom molded rubber parts provide superior sealing performance in automotive engines, doors, and windows. They offer excellent protection from oil, heat, and pressure, ensuring reliable performance in vehicle systems.

Industrial Machinery Components

We produce custom rubber parts for heavy-duty machinery, providing vibration damping, sealing, and protection. These components help extend machinery life by reducing wear and tear while improving overall performance.

Construction Equipment

Our custom rubber parts, such as seals and gaskets, are essential components for construction equipment, ensuring durability and stability under extreme working environments.

Aerospace Applications

Precision and durability are crucial in aerospace systems. Our molded rubber components meet stringent specifications, offering reliable sealing and protection in extreme conditions.

Custom Parts for Specialized Applications

We offer bespoke molding services for electronic components, marine applications, and customized engineering projects, ensuring that the final product meets your exact requirements.

Why Choose Our Molded Rubber Solutions?

Expertise in Rubber Moulding

With years of experience in custom rubber moulding, we provide reliable solutions across various industries. Our team ensures each part is created to the highest standards, guaranteeing optimal performance and durability.

Comprehensive Materials Selection

We offer an array of rubber compounds designed to meet the specific requirements of each application, ensuring their properties align with your project needs.

Advanced Moulding Technology

Our state-of-the-art moulding facilities enable us to produce high-precision rubber parts with impeccable consistency and quality. From complex geometries to simple designs, we manufacture parts to meet your exact specifications.

Fast Turnaround and Competitive Pricing

We understand the importance of meeting deadlines and offer quick production times to keep your project on schedule. Our efficient processes also allow us to offer highly competitive pricing without compromising quality.

Looking for Custom Bespoke Molded Rubber Solutions?

If you're searching for high-quality custom molded rubber components for your project, reach out to us today. We provide bespoke rubber parts tailored precisely to your requirements, whether for automotive, industrial, or specialized applications. Our team is ready to assist.