Rubber Injection Molded Automotive Bellows - Outstanding Quality for a Smooth Drive

I. Product Overview

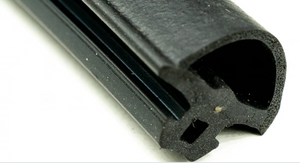

Engineered to withstand the challenging conditions of modern automotive environments, our rubber injection molded bellows provide essential protection for vehicle pipeline systems. These components utilize advanced molding techniques to offer exceptional flexibility, superior sealing properties, and extended durability. By ensuring the reliable operation of critical internal mechanisms, they serve as a vital solution for enhancing overall vehicle safety and performance.

II. Exquisite Technology

Advanced Injection Molding Technology

We adopt the cutting-edge rubber injection molding process in the industry. High-quality rubber raw materials carefully prepared are injected at high speed and with precision into specially made mold cavities under precisely controlled temperature and pressure conditions. This process ensures the uniform cross-linking of rubber molecules, endowing the finished bellows with outstanding physical properties such as high strength and high elasticity, enabling it to easily cope with vibrations, twists, and stretches during vehicle driving.

Precision Mold Research and Development

The professionally designed and manufactured molds are the guarantee of high product precision. The mold surfaces have undergone fine grinding and special treatment, not only ensuring the smooth and flawless appearance of the bellows but also enabling the product to achieve millimeter-level dimensional accuracy, perfectly fitting various automotive pipeline systems, facilitating easy installation and effectively reducing assembly costs.

III. Outstanding Features

Super Durability

We select high-quality rubber materials rich in special anti-aging and anti-wear additives. After strict testing and verification, the service life of this bellows far exceeds that of ordinary similar products in harsh environments such as high temperature, high humidity, and sandstorms. Whether it is protecting the engine cooling pipelines under the frequent start-stop conditions in urban traffic jams or safeguarding the chassis components during off-road driving, it can always stand firm and protect the automotive pipelines.

Excellent Sealing Performance

The unique corrugated structure design, combined with the precise molding process, gives the product outstanding sealing performance. It can effectively prevent water vapor, dust, impurities, and other substances from invading the pipelines, ensuring the pure operation of the vehicle's braking, fuel, and cooling systems, reducing the risk of failure and enhancing the overall reliability of the vehicle.

High Flexibility

Based on the actual dynamic requirements during vehicle operation, the optimized bellows design provides excellent flexibility. Even under extreme working conditions such as sharp turns and large bumps of the vehicle, it can flexibly adapt to the expansion and bending changes of the pipelines, avoiding pipeline rupture or leakage caused by rigid pulling and ensuring driving safety.

IV. Customization Services

We deeply understand that different vehicle models and application scenarios have diverse requirements for bellows. Therefore, we offer comprehensive customization services:

Size Customization: From micro cars to heavy trucks, regardless of the pipe diameter and length requirements, we can provide precise customization to ensure a perfect fit for your vehicle's pipeline layout.

Performance Customization: According to special working conditions, such as in frigid regions or high-temperature desert areas, we can adjust the rubber formula to enhance the cold and heat resistance of the bellows, meeting the driving needs in special environments.

V. Quality Assurance

Strict Raw Material Inspection

Before each batch of rubber raw materials enters the factory, they undergo multiple professional inspection procedures, ranging from hardness and tensile strength tests to chemical composition analysis, ensuring the stable and reliable quality of the raw materials and laying a solid foundation for high-quality products.

Whole-process Production Monitoring

During the production process, an advanced automatic monitoring system is introduced to monitor and control parameters of each injection molding stage in real time, including temperature, pressure, and injection speed, ensuring the consistency of product quality.

Finished Product Inspection and Quality Control

In accordance with international automotive industry standards, a variety of high-end testing equipment is used to conduct comprehensive inspections of the finished bellows. Tests such as airtightness tests, pressure resistance tests, and fatigue life tests are carried out. Only when all indicators meet the standards will the products be allowed to leave the factory, ensuring that every bellows you receive is of excellent quality.

VI. Application Cases

Over the years, our rubber injection molded automotive bellows have been widely applied to multiple models of various well-known automotive brands. In [Specific Brand Model 1], it helps to enhance the chassis protection performance and reduce the after-sales maintenance rate; in [Specific Brand Model 2], it provides excellent protection for the engine cooling pipelines, ensuring the stable operation of the vehicle in extremely high-temperature environments. Numerous successful cases testify to the strength of our products and make us a trustworthy choice.

VII. Customer Services

Professional Technical Consultation: We have an experienced technical team ready to answer your technical questions regarding product selection, installation and use, and performance optimization at any time.

Quick Response After-sales Service: Once you encounter any product quality problems or usage difficulties, we promise a quick response within 24 hours and provide solutions to ensure that your vehicle maintenance is not affected.

Choose our rubber injection molded automotive bellows, choose professionalism, quality, and peace of mind. Inject lasting power into your vehicle and embark on a worry-free journey. Contact us now to start your customization journey!</doubaoccanvas>

If you have any further suggestions for modification, such as adding or reducing content, adjusting the structure, etc., please feel free to let me know.