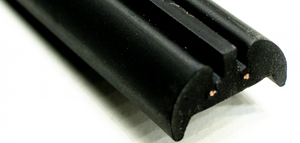

EPDM Foam Die-Cutting Solutions for Automotive Sealing, Cushioning, and Noise Reduction

Introduction:

Engineered to meet the rigorous standards of the automotive industry, our EPDM foam die-cutting solutions deliver exceptional performance. Renowned for its durability, flexibility, and weather resistance, EPDM foam is the premier choice for sealing, cushioning, and noise attenuation. Leveraging advanced precision die-cutting, we produce custom-fit components that ensure superior sealing and soundproofing for doors, windows, and engine compartments.

Key Features:

1. Precision Die-Cutting for Custom Fit

Our die-cutting process ensures that each EPDM foam component is custom-fit to your specifications, providing optimal sealing, noise reduction, and cushioning in automotive applications. The foam can be easily adapted to the contours of various car parts, ensuring a secure and efficient fit.

2. Adhesive-Backed Foam for Easy Installation

Our die-cutting with adhesive foam options allow for easy installation, reducing the need for additional fasteners or adhesives. The strong adhesive backing ensures the foam stays securely in place, even in demanding automotive environments.

3. Excellent Noise and Vibration Reduction

The structure of EPDM foam provides exceptional soundproofing and vibration absorption, making it ideal for reducing noise in vehicles. Whether used in door panels, dashboards, or engine compartments, this foam helps maintain a quieter and more comfortable cabin environment.

4. Weather and Chemical Resistant

EPDM foam is highly resistant to weather conditions, UV exposure, and chemicals, ensuring long-term performance in automotive applications. It maintains its sealing and insulating properties even in extreme temperatures and harsh environments.

Applications:

Automotive Sealing

Our EPDM foam provides excellent sealing for doors, windows, and other critical areas of the vehicle, protecting against water, dust, and air leaks.

Cushioning for Automotive Components

Designed for use in areas where shock absorption is needed, our EPDM foam helps reduce vibrations and protects sensitive automotive components from wear and tear.

Noise Reduction

Our EPDM foam die-cutting solutions are perfect for automotive noise reduction applications, offering superior soundproofing for vehicle interiors, including doors, dashboards, and engine compartments.

Why Choose Our EPDM Foam Die-Cutting Solutions?

Our EPDM foam die-cutting solutions are designed for precision, performance, and durability. Whether for sealing, cushioning, or noise reduction, our custom die-cut foam components deliver high-quality results tailored to the specific needs of automotive applications. With the option for adhesive-backed foam, installation is made simple and efficient, ensuring reliable performance over the long term.

Customization Options:

We offer fully customizable EPDM foam die-cutting services, including:

Custom shapes, sizes, and thicknesses

Adhesive backing options

Specialized foam density and hardness to meet your project requirements

Industries Served:

Automotive Manufacturing

Custom Car Modifications

Industrial Equipment

HVAC Systems

Conclusion:

Our EPDM Foam Die-Cutting Solutions offer a versatile and reliable option for automotive sealing, cushioning, and noise reduction. With precision cutting, adhesive backing, and excellent weather resistance, these foam components are designed to meet the highest industry standards. Whether you're looking to enhance soundproofing or improve component protection, our EPDM foam is the ideal choice for any automotive application.