Overview

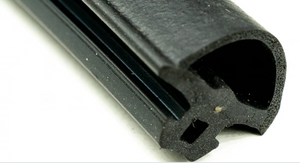

Our automotive rubber molded products are crafted to meet the highest industry standards, providing superior performance in sealing, vibration damping, and noise reduction. Ideal for automotive manufacturers and aftermarket suppliers, these components are tailored to enhance vehicle reliability and comfort.

Key Features:

Durability: Made from high-quality rubber compounds resistant to wear, tear, and aging.

Temperature Resistance: Withstands extreme temperatures, from -40°C to 150°C (-40°F to 302°F).

Customizable: Available in various shapes, sizes, and materials to meet specific automotive requirements.

Sealing Excellence: Ensures leak-proof performance for critical automotive systems.

Vibration Damping: Reduces noise and vibration, enhancing driving comfort and vehicle longevity.

Applications:

Engine mounts and gaskets

Door and window seals

Suspension bushings

HVAC system components

Fluid handling systems (e.g., fuel, oil, and coolant)

Why Choose Us?

Precision Manufacturing: Advanced molding techniques ensure consistent quality and performance.

Industry Expertise: Decades of experience in automotive rubber solutions.

Custom Solutions: Tailored designs to meet your unique specifications.

Global Standards: Compliant with ISO, ASTM,IATF16949, and automotive industry certifications.

Technical Specifications:

Material Hardness: 40-90 Shore A

Tensile Strength: Up to 20 MPa

Elongation at Break: Up to 500%

Color Options: Black (standard), custom colors available upon request.

Ordering Information:

MOQ: 500 pieces (custom orders may vary).

Lead Time: 2-4 weeks (depending on order size and customization).

Packaging: Standard export packaging, customized options available.