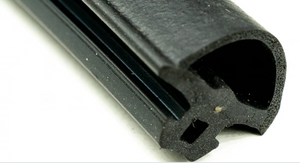

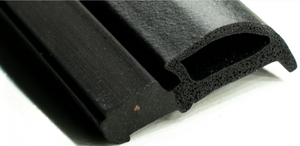

What is EPDM Rubber?

EPDM (Ethylene Propylene Diene Monomer) rubber is a type of synthetic rubber known for its exceptional weather resistance, flexibility, and durability. It is widely used in various sealing applications, particularly for outdoor and harsh environments.

Characteristics of Molded EPDM Sealing Gaskets

Weather Resistance: EPDM rubber is highly resistant to UV radiation, ozone, and extreme weather conditions, making it ideal for outdoor sealing applications.

Flexibility and Elasticity: Maintains its flexibility and elasticity over a wide temperature range (-50°C to 150°C / -58°F to 302°F), ensuring a consistent and reliable seal.

Water and Steam Resistance: Excellent resistance to water, steam, and moisture, preventing degradation and maintaining sealing properties.

Chemical Resistance: Resistant to a variety of chemicals, including acids, alkalis, and polar solvents, enhancing its versatility in different industrial environments.

Thermal Insulation: Provides good thermal insulation, helping to maintain temperature control and reduce energy loss.

Applications

Automotive Industry:

Used in door and window seals, weatherstripping, and gaskets to provide a reliable seal against environmental elements, reduce noise, and enhance thermal insulation.

Building and Construction:

Applied in roofing membranes, window seals, expansion joints, and pipe seals to ensure waterproofing, insulation, and protection from weather conditions.

HVAC Systems:

Industrial Equipment:

Electrical Insulation:

Advantages

Durability: EPDM rubber offers a long lifespan due to its resistance to aging, weathering, and chemical exposure.

Versatility: Performs well in a variety of environments, making it suitable for a wide range of sealing applications.

Cost-Effective: Provides an economical solution for sealing needs, offering a good balance between performance and cost.

Low Maintenance: Resistance to environmental factors reduces the need for frequent maintenance and replacement.